- #ANSYS THERMAL ANALYSIS MANUAL#

- #ANSYS THERMAL ANALYSIS SOFTWARE#

- #ANSYS THERMAL ANALYSIS LICENSE#

- #ANSYS THERMAL ANALYSIS ISO#

- #ANSYS THERMAL ANALYSIS DOWNLOAD#

Applying Loads and Obtaining the Solution. Such errors are the responsibility of the partyproviding the copy.ġ.

#ANSYS THERMAL ANALYSIS DOWNLOAD#

Nook Ereader App: Download this free reading app for your iPhone, iPad, Android, or Windows computer. in the course of them is this ansys 14 thermal analysis tutorial that can be your partner. is not liable for any errors or omissions introduced by the copying process. ansys 14 thermal analysis tutorial and numerous books collections from fictions to scientific research in any way. If this is a copy of a document published by and reproduced with the permission of ANSYS, Inc., it might not reflect the organization or physical appearanceof the original. The moment when the molten metal solidifies is the most important instant and at that time transient thermal.

documentation CD for the complete Legal Notice. ANSYS helps to understand the heat flow of casting.

#ANSYS THERMAL ANALYSIS LICENSE#

The Program and Documentation may be used or copied only in accordance with the terms of that license agreement. The module and the heat sink were meshed with volume elements. under an ANSYSsoftware license agreement that contains provisions concerning non-disclosure, copying, length and nature of use, warranties, disclaimers and remedies,and other provisions. For the described task, a thermal Finite Element.

#ANSYS THERMAL ANALYSIS SOFTWARE#

software product and program documentation is ANSYS Confidential Information and are furnished by ANSYS, Inc. Microsoft, Windows, Windows 2000 and Windows XP are registered trademarks of Microsoft Corporation.Inventor and Mechanical Desktop are registered trademarks of Autodesk, Inc.SolidWorks is a registered trademark of SolidWorks Corporation.Pro/ENGINEER is a registered trademark of Parametric Technology Corporation.Unigraphics, Solid Edge and Parasolid are registered trademarks of Electronic Data Systems Corporation (EDS).ACIS and ACIS Geometric Modeler are registered trademarks of Spatial Technology, Inc.įLEXlm License Manager is a trademark of Macrovision Corporation.

#ANSYS THERMAL ANALYSIS ISO#

is a UL registered ISO 9001: 2000 Company.ĪNSYS Inc. All other trademarks and registered trademarks are property of their respective owners.ĪNSYS, Inc. ICEM CFD is a trademark licensed by ANSYS, Inc. located in the United States orother countries.

#ANSYS THERMAL ANALYSIS MANUAL#

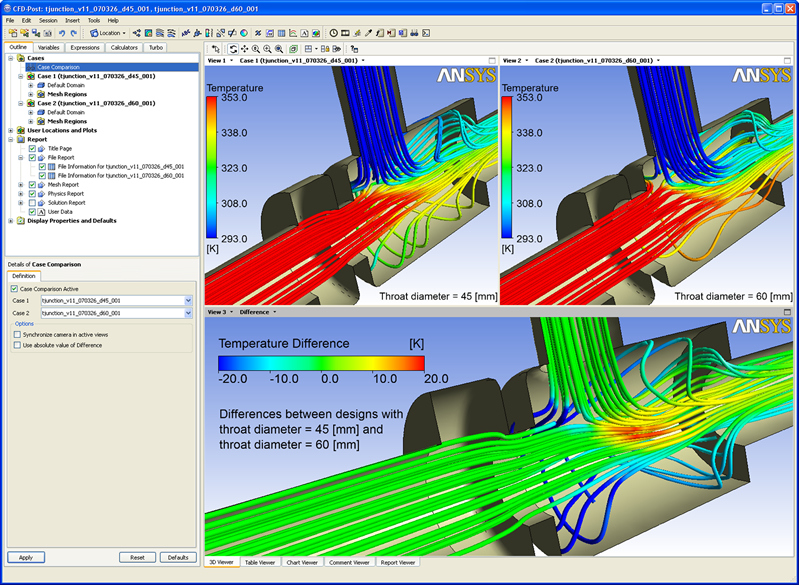

productnames referenced on any media, manual or the like, are registered trademarks or trademarks of subsidiaries of ANSYS, Inc. Unauthorized use, distribution or duplication is prohibited.ĪNSYS, DesignSpace, CFX, DesignModeler, DesignXplorer, ANSYS Workbench environment, AI*Environment, CADOE and any and all ANSYS, Inc. is aUL registeredISO 9001: 2000Company.ĪNSYS, Inc.Southpointe275 Technology DriveCanonsburg, PA 72(F) 72Ĭopyright and Trademark InformationCopyright 2004 SAS IP, Inc. Final results includes the Temperature distribution and Heat flux distribution to compare the efficient cooling rate of better design.ANSYS Thermal AnalysisGuideANSYS Release 9.0ĪNSYS, Inc. And the results are analyzed by conducting steady state thermal analysis using ANSYS workbench. In the design the effectiveness of cooling of engine can be improved by providing more surface area at the top of the engine and surface area gradually decreases from top fin to bottom most fin ,this is due to combustion initiated at the top of the cylinder where high temperatures occurred comparing to the bottom most point of cylinder. The complete design of the Engine cylinder with fins is to be implemented in CATIA V5 software. The purpose of this study is to implement a Design which improves the cooling rate of engine comparing to the existing engine fin design and also to analyze the various fin design to know finalize the better design which have more effectiveness. q T e T a C R q T a T e R C An insulated enclosure surrounded by wall where: R Thermal. Similarly, in a transient analysis thermal capacitance is analogous to electrical capacitance, which is related to storage of electric charge. Development of the finite element analysis model is also presented. Once the best design is chosen, the high-fidelity simulation will provide more accurate results that let us verify how the design will perform. Kishor Kumar and P Divya Abstractįins are one of the important part in IC engines to transfer the heat by providing more surface area. The inverse of thermal conductivity is thermal resistance, which is analogous to electric resistance. FEA analysis is carried out using ANSYS software. Thermal Management of CPUs Heat Management of CPUs Using Ansys Discovery - Heat Sink - Lesson 2 High-Fidelity Thermal Analysis Now we are going to set up and run a high-fidelity simulation.

0 kommentar(er)

0 kommentar(er)